Wooden Fences with Metal Posts: Durable, Affordable, Easy to Install

- Eric Lafleche

- Dec 18, 2025

- 14 min read

Wood fences with metal posts marry the warm look of timber with the steadfast strength of steel or aluminium. Metal posts set in concrete keep boards off the damp ground and hold your fence plumb through Ottawa–Gatineau’s humid summers and freeze-thaw winters.

Why Wooden Fences With Metal Posts Excel

The real advantage comes from isolating wood from soil moisture. Metal posts form a sturdy backbone, so panels stay straight and true.

Anchored In Concrete: Prevents rot and wobble in high-moisture soils

Stainless-Steel Brackets: Secure boards without rust or staining

Uniform Rails: Horizontal supports keep panels flush

Lower Repair Cycles: Fewer replacements drive down long-term costs

Visual Appeal And Customisation

With metal-post supports, you’re not stuck with off-the-shelf styles. Powder-coated finishes, decorative caps and adjustable brackets add flair on demand.

Powder-coated posts in custom colours complement stained timber

Post caps range from flat shields to ornamental finials

Mix textures by pairing smooth metal with ribbed or rough-sawn wood

Performance In Harsh Climates

Clay-heavy soils and repeated freeze-thaw cycles can push wooden posts out of plumb. Galvanized or powder-coated metal posts, set below the frost line, lock in stability.

Like a resilient backbone, metal posts resist twisting and leaning, delivering decades of consistent performance.

Cost Versus Lifespan

Hybrid fences typically cost 10–30% more upfront than all-wood structures. But when timber posts need replacement every 7–10 years and metal-supported posts last 20+ years, the numbers favour hybrids.

Upfront Cost Difference: All-wood vs. metal-post hybrids

Replacement Cycle: 7–10 Years for timber, 20+ Years for metal

Maintenance: Annual wood sealing vs. occasional metal touch-ups

To make it easy, here’s a quick side-by-side look at how metal-post supports measure up against traditional timber posts across critical factors.

Key Benefits And Comparisons

Aspect | Metal Posts | Wood Posts |

|---|---|---|

Durability | 20–30 Years in ground contact | 7–10 Years before decay |

Maintenance Frequency | Touch-ups every 3–5 years | Seal and stain yearly |

Lifecycle Cost | Moderate initial, lower over 20 years | Low initial, higher long term |

Curb Appeal | Clean lines with metal-wood contrast | Rustic warmth with natural grain |

Actionable Insight

Run a simple 20-year cost analysis comparing wood replacements versus one-time metal investments.

Factor in annual sealing and maintenance when budgeting for your fence.

If your budget allows, opt for metal posts to minimize mid-life interventions and labour calls.

Next, let’s dive into material options and installation steps to maximise these benefits.

How Wooden Fences With Metal Posts Work

Metal posts serve as the backbone of a hybrid fence, much like a building’s steel frame. They keep wooden boards from warping or sagging, ensuring a crisp, straight line over time.

You’ll typically find galvanized steel or powder-coated aluminium posts in various profiles and gauges. That means you can opt for a heavier gauge steel post in areas prone to strong gusts.

Post Anchoring And Footing Basics

Getting the footing right is crucial in Ottawa–Gatineau’s freeze-thaw climate. Here’s the quick rundown:

Hole Depth: About one-third of the fence height, plus 6 inches below frost depth

Concrete Mix: High-strength, air-entrained formula to fend off freeze-thaw damage

Gravel Base: 4–6 inches of tamped gravel at the bottom for drainage

Footing Width: 4–6 inches wider than the post diameter

For horizontal support, steel rails or board-on-board brackets hold up the timber. Rails slip into welded brackets or secure with stainless-steel screws, keeping boards off the ground and perfectly aligned.

Attach brackets at the top, middle and bottom for even load transfer

Use stainless fasteners to prevent staining and galvanic corrosion

Align everything with a laser level or a taut string line

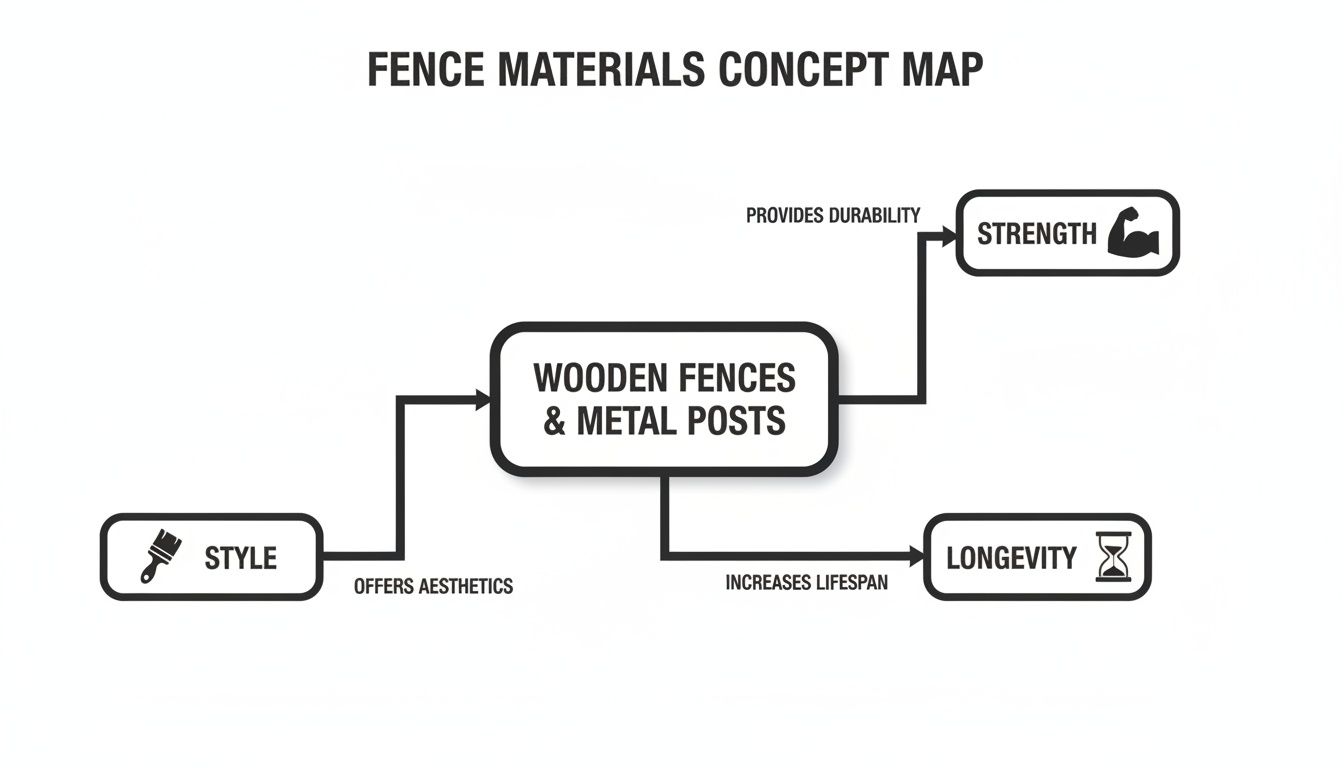

Below is an infographic illustrating the core benefits of strength, longevity and style with wooden fences on metal posts.

The diagram shows how a metal-post skeleton boosts strength, extends longevity, and enhances style with minimal upkeep.

Finishing And Corrosion Protection

A protective finish—galvanizing or powder-coating—forms a barrier against rust. You can even match post colours to wood stains, blending seamlessly with cedar, redwood or pressure-treated pine.

Caps and trim pieces seal off post tops and edges, keeping moisture out. Stainless anchors and hardware round out a weather-resistant system that stays plumb and straight year after year.

Post Profile And Gauge Selection

Picking the right profile and gauge depends on wind loads and wood weight. Here’s a quick comparison:

Post Gauge | Best For |

|---|---|

12 | High-wind zones |

14 | Standard privacy |

And here’s how spacing typically breaks down:

Fence Type | Spacing |

|---|---|

Privacy | 6–8 ft |

Open properties | 5 ft |

For detailed footing depth guidance, read our article How Deep Should a Fence Post Be a Practical Guide.

By weaving a steel frame with timber boards, you end up with a fence that resists rot, stays plumb through freeze-thaw cycles, and retains a polished look for decades.

Actionable Insight

Choose your post gauge based on local wind exposure and wood weight to avoid overbuilding.

Secure stainless fasteners at each bracket to stop galvanic corrosion before it starts.

Confirm hole dimensions with form tubes for consistent, drainage-friendly footings.

Benefits Compared To Wood Posts

Metal fence posts have a clear edge over timber when it comes to ground-contact durability. Untreated wood buried in moist soil often begins to rot and warp within 7–10 years, leading to misaligned boards and climbing maintenance costs.

Rot Resistance: Metal won’t succumb to decay, cutting down on mid-life replacements.

Stable Alignment: Steel posts stay plumb through freeze–thaw cycles, so your fence line remains straight.

Pest Proofing: Termites and wood-eating fungi simply can’t feast on steel.

On top of that, metal’s noncombustible nature offers valuable fire resistance—an important factor in wildfire-prone regions. Local data shows hybrid fences with steel supports require 50% fewer maintenance visits over two decades than their all-wood counterparts.

Wood posts demand annual sealant and frequent staining.

Steel supports only need a quick corrosion-resistant coating check every 3–5 years.

The result? Lower labour calls and smoother budgeting.

Even though metal posts cost more upfront, you’re likely to push major fixes out by 10–15 years, freeing up funds for other projects.

Lifecycle Cost Comparison Of Post Types

When weighing installations, it’s helpful to consider both the first-cost and long-term outlays. Here’s a side-by-side look:

Metric | Wood Posts | Metal Posts |

|---|---|---|

Expected Lifespan | 7–10 Years | 20+ Years |

Replacement Cycles (20 Years) | 2–3 mid-life replacements | 0–1 minimal interventions |

Total 20-Year Cost | High due to recurring repairs | Moderate with fewer service calls |

By selecting steel supports, you shift your cost curve downward over decades, minimising surprises and stretching every dollar further.

Actionable Insight

Inspect soil moisture to anticipate wood decay and plan for metal if conditions are damp.

Set a reminder for metal post touch-ups every 3–5 years to extend lifespan.

In fire-risk areas, factor steel’s noncombustible edge into your material selection.

Case Studies And Data

In California public-works projects, metal-post fencing runs about $7.00 per linear foot versus roughly $12.00 per linear foot for wood posts. You can explore the California Department of Transportation’s contract history on steel vs wood fence posts here.

On the residential front, a 6-ft wood privacy fence typically costs $15–$55 per linear foot, with pricier materials or tricky terrain pushing up expenses. Field reports highlight that steel posts may be 40–60% more expensive per unit than untreated wood, yet they remain serviceable for 20+ years in damp soils.

A suburban 200-ft fence could see an extra $300–$600 investment for metal posts.

Avoid mid-life replacements that often run $500–$1,200 and disrupt landscaping.

Noncombustible steel adds a layer of safety in fire-vulnerable areas.

Overall, factoring in replacement frequency tips the scales in favour of metal supports for board-on-board fences.

When Investing Pays Off

Imagine a 200-ft hybrid fence in your backyard. The initial steel-post premium translates to a few hundred extra dollars, but you’ll reap real savings down the road:

Posts stay perfectly plumb through freeze–thaw seasons, slashing realignment work.

Labour costs drop when there’s no rot or shifting to fix.

Steel’s fire resistance enhances safety in wildfire-at-risk zones.

“After a decade, our metal posts held everything straight and saved us significant labour costs,” recalls a local homeowner.

Over 20 years, a hybrid fence with metal posts can cut total ownership costs by 15–20% compared to an all-wood structure. Annual upkeep time plummets from 12 hours to about 3 hours, giving you more weekends free.

Fewer service calls and less sealant go a long way.

These advantages underscore why combining wood panels with metal posts delivers remarkable value—and peace of mind—for decades ahead.

Next, we’ll dive into material choices, coatings and regional cost considerations so you can pick posts and boards built to last in the Ottawa–Gatineau climate.

Choosing Materials For Posts And Boards

Picking the right mix of steel posts and wood boards isn’t just about looks—it’s the foundation for a fence that stays true and handsome for decades. Every decision, from metal thickness to wood species, shapes how your fence stands up to wind, moisture and daily wear.

Post Material Options

When it comes to supporting your fence, posts carry the load—literally. Here’s how to decide:

Galvanized Steel Delivers a rock-solid core and excellent rust resistance right where it meets the ground.

Powder-Coated Steel Offers endless colour choices and a UV-stable finish that won’t peel under Ottawa’s sun.

Aluminium Light enough for one person to handle yet immune to corrosion over time.

Stainless Hardware Brackets and screws in stainless steel stop galvanic staining and stay tight year after year.

These options shine whether you’re facing gusty afternoons, freeze–thaw cycles or the salt spray off spring roads.

Board Material Choices

The wood you select sets the tone—warmth, texture and durability all come down to species:

Cedar Naturally rich in oils that fend off rot and insects without chemicals.

Redwood Boasts deep, reddish hues and eye-catching grain. Expect a premium price for its beauty.

Pressure-Treated Pine Balances a friendly price tag with basic decay resistance. Learn more in our guide on Pressure-Treated Lumber A Practical Guide For Outdoor Projects.

Painted Spruce Smooth, uniform boards that let you control the finish and stay gentle on your budget.

Each species differs in grain patterns, colour tones and how it absorbs stain.

Sealing And Finishing Steps

A proper finish does more than look good—it wards off moisture and UV damage:

Clean every surface with a wood-safe prep cleanser.

Evenly coat boards with a water-repellent stain or sealant.

Prime steel posts using a corrosion inhibitor, then apply your chosen topcoat.

Always respect cure times—overnight drying ensures each layer bonds fully.

Material Options And Cost Ranges

Here’s a quick snapshot of material costs to help with budget planning:

Material Combination | Cost Per Linear Foot |

|---|---|

Cedar boards on galvanized steel posts | $35–$55 |

Redwood boards on powder-coated steel posts | $40–$60 |

Pressure-Treated Pine boards on galvanized posts | $30–$45 |

Painted Spruce on aluminium posts | $28–$42 |

This table lays out how different pairings influence your per-foot investment and lifespan.

By comparing these figures, you’ll see that hybrid setups push costs toward the upper band but often extend major repairs by 10–15 years. In California, a 6-ft privacy fence typically runs $25–$55 per linear foot (materials + labour). Specialty combinations—like wood boards on galvanized posts with stainless hardware—can add $10–$30+ per post assembly compared to simple wood-post builds.

A homeowner planning a 200-ft 6-ft fence in California in 2025 might budget between $5,000 and $11,000. Choosing galvanized steel over untreated wood can raise initial costs by 10–30% but often saves on a major post replacement down the road. Read the full findings on fence costs from Metal Gate Masters.

Actionable Tips For Material Selection

Start by mapping sun exposure, soil moisture and your maintenance schedule. These factors steer you toward the right metal finish and wood species.

Tip 1: Order small samples to see stain absorption and colour in your yard.

Tip 2: Compare corrosion warranties and upkeep requirements side by side.

Tip 3: Ask contractors if custom powder-coat colours carry hidden fees.

Seeing boards and posts together in natural light removes guesswork—and delivers confidence in your final choice.

For example, one homeowner paired cedar boards with slate-grey powder-coated posts at $45 per foot. The result? A stunning fence that cut annual staining time by 50% and banned rust worries for good.

Choose wisely, and your fence will reward you with style and reliability for years to come.

Planning Installation In Ottawa Gatineau Climate

Ottawa–Gatineau’s big temperature swings and heavy clay soils demand extra care when setting up wooden fences on metal posts. Frost can heave the ground, so your footings need to sit below the freezing layer. In the sections that follow, we’ll walk through footing depths, concrete mixes, permit triggers and licence steps—everything you need to plan a reliable, long-lasting fence.

Learn more about frost depth requirements in our article Your Guide to Frost Depth in Ontario.

Local Footing Depth Requirements

To keep your posts from popping out in spring, set them below the frost line—an average of 1.2 metres in this region. Think of your footing like a tree’s roots: the deeper and wider they go, the more stable they are.

Dig holes at least 1.2 m deep to clear the freeze zone.

Lay 10 cm of crushed stone at the base for better drainage.

Flare out 15 cm around each post to create a bell-shaped footing.

Use a laser level to centre posts before pouring concrete.

Concrete Mix And Anchoring Techniques

A strong concrete mix is your fence’s backbone against freeze-thaw cycles. Air-entrainment adds tiny bubbles that absorb stress, while a low water-to-cement ratio prevents cracks.

Combine 1 part cement, 2 parts sand and 3 parts aggregate.

Stir in an air-entraining agent following the manufacturer’s guidelines.

Aim for a slump of 50–75 mm for optimal durability.

Pour immediately after mixing—waiting leads to cold joints.

Navigating Permits And Bylaws

Municipal rules can trip you up if you’re not careful. In Ottawa and Gatineau, fences over 1.2 m near sidewalks or posts within 1 m of a pool usually need approval.

Check setback rules with your local planning office before you dig.

Apply for a pool-enclosure permit if your posts encroach on a pool barrier.

Book your inspections both before and after post installation.

Mark your property lines clearly to avoid neighbour disputes.

Case Studies In Ottawa Gatineau

Local teams tweak curing times and add rebar to handle wet springs and heavy snow. One FenceScape crew shaved four weeks off a project by using quick-set mixes—yet the fence stood perfectly plumb after two brutal winters.

“Using air-entrained concrete and steel rebar cut post-levee by half, keeping posts perfectly aligned,” recalls a FenceScape installer.

Step By Step Installation Roadmap

Think of this as your recipe for success: each step builds on the last, adapting to frost depth and soil type so you end up with a straight, weatherproof fence.

Mark post spots using string lines and stakes at 6–8 ft centres.

Dig holes, add the gravel base and plumb your metal posts.

Pour your air-entrained concrete mix and brace the posts until set.

Attach brackets, then fasten the wood boards at uniform heights.

Check each post for plumbness; tweak brackets if needed.

Backfill and grade around posts, directing water away from the base.

Actionable Insight

Confirm local frost line depth and adjust hole depth accordingly before you start.

Use quick-set concrete when time is tight, but brace posts firmly until cured.

Always brace posts during freeze–thaw cycles to avoid mid-cure movement.

Best Practices For Weather Variations

When spring thaws flood your yard, it’s tempting to rush. Instead, cover holes with plywood and let water drain before you pour. On dry summer days, dig a touch deeper and keep your mix moist so it cures evenly.

In soggy springs, shield holes to keep out debris.

Use quick-set concrete when a fast cure is critical.

Wait for two dry days before you frame and fasten.

Brace posts during freeze-thaw cycles to prevent shifting.

Inspection Checklist For Long Term Stability

A quick annual check can save you big headaches. Look for small shifts, rust spots or cracks before they turn into major repairs.

Verify posts with a taut string line each spring.

Check brackets and welds for any sign of corrosion.

Note board gaps larger than 5 mm—they can widen fast.

Repair hairline cracks at the concrete base early.

Common Challenges And Solutions

Clay soil clinging to posts can interfere with curing. A biodegradable release agent solves that by letting forms slip off cleanly. Swing gates, meanwhile, demand beefier footings and anchor plates to handle the extra torque.

Use form tubes to ensure uniform hole diameters.

Tie in rebar for greater tensile strength.

Stagger posts on slopes to keep your string line straight.

Grease gate hardware with marine-grade lubricant for smooth swings.

Professional Assistance When Needed

If your site has tricky grades, tight timelines or complex permit issues, the FenceScape team has your back. We handle everything from planning to final inspection, cutting your risk and guaranteeing code compliance.

Get a free estimate and project timeline from FenceScape.

Contact us today.

Maintenance Tips And Compliance Requirements

A little attention goes a long way in keeping a wooden fence with metal posts looking sharp and standing strong. Regular checks help you catch rust, warping or concrete cracks before they become major hassles. A simple seasonal routine can easily extend your fence’s lifespan.

Seasonal Maintenance Routines

To start, give your anchor bolts a quick once-over. Spot any early corrosion and tighten loose connections right away.

Next, clean the wood panels with a mild detergent, rinse thoroughly and allow them to dry completely before applying sealant. A fresh coat every 1–2 years keeps moisture at bay.

Check Metal Posts for surface rust and touch up paint as needed.

Clean Brackets using a wire brush, then spray on an anti-rust solution.

Lubricate Hardware like hinges and latches to maintain smooth operation.

Spotting And Fixing Early Issues

Warped boards can pinch neighbours and strain your brackets. Left unchecked, small problems quickly escalate.

Early detection cuts repair costs by 50% and stops minor issues from growing.

When a post loosens, follow these steps:

Realign the post using a level and secure it with braces.

Pour a fresh batch of air-entrained concrete mix around the base.

Smooth and slope the top to channel water away from the footing.

Compliance And Curb Appeal Refresh

In Ottawa–Gatineau, front yard fences max out at 1.2 m while side and backyard fences can reach 1.8 m. Setbacks call for posts at least 0.6 m from property lines, and gates must meet specific hardware standards.

Pool enclosures require a minimum height of 1.2 m plus self-closing gate mechanisms.

Non-climbable fittings and mesh screening are mandatory in some zones.

Any fence over 1.2 m or within 1 m of a pool needs a permit.

A simple curb-appeal boost—like horizontal cedar accents or mixed-material insets—often flies under the permit radar. Even adding trim at under $5 per linear foot can modernise your fence in an afternoon.

In coastal high-moisture areas of California, metal posts outperform untreated wood by resisting rot. Region guides note that pine or redwood posts degrade in 8–12 years, whereas galvanized steel and stainless hardware deliver 15–30+ years of service. Learn more about coastal fence performance on Fence Specialties.

Coastal sites avoid a full post cycle for every 100 feet, cutting long-term upkeep by one cycle.

Actionable Insight

Inspect for rust and hairline cracks at the start of each season to catch problems early.

Reapply sealant in line with manufacturer guidelines to maintain water repellence.

Tighten brackets and hardware annually to prevent board misalignment.

FenceScape Services And Financing

FenceScape offers tailored maintenance plans and inspection services to suit every budget.

Seasonal inspections to catch rust, wood decay and concrete wear.

Board resealing and staining to keep moisture out.

Hardware tightening and post realignment for rock-solid support.

Neighbourhood group installs slash per-home costs and speed up timelines. Flexible financing options let you spread payments without a bulky upfront bill.

Trust proactive care to extend fence life by 20%, saving you time and money.

Our in-house team handles permits, inspections and bylaw paperwork from start to finish. We use quick-set concrete mixes and precision alignment tools to keep every post perfectly plumb.

End-to-end permit and inspection management.

Labour and materials warranty on all services.

Dedicated support for scheduling and reminder follow-ups.

Neighbourhood discounts and financing make expert upkeep affordable. Stay compliant, boost curb appeal and protect your property investment.

Visit FenceScape or call our office to book a maintenance service or compliance review today, and secure your warranty for reliable annual upkeep.

Frequently Asked Questions

Choosing a wooden fence with metal posts raises plenty of practical questions. Below are some of the top concerns we hear from Ottawa–Gatineau homeowners.

How Long Do Metal Posts Last Compared To Wood Posts Galvanized steel or powder-coated aluminium posts typically stay solid for 20–30 years. By comparison, pressure-treated wood posts often need replacing after about 10–15 years.

Can I Install A Wooden Fence With Metal Posts Myself If you’ve mixed concrete and used an auger before, a DIY install is within reach. That said, professional installers nail the frost-resistant footings and perfect alignment every time.

What Maintenance Do Metal Posts Require Give your posts a once-a-year check for rust spots. Then, apply a corrosion-resistant paint or sealant as needed, and tighten any stainless-steel hardware to keep everything snug.

Are Wooden Fences With Metal Posts More Expensive Upfront Yes—metal posts and stainless fasteners usually add about 10–30% to the initial cost. However, that extra investment often offsets mid-life repairs over the fence’s 15–20-year service life.

Beyond lifespan and cost, permits and bylaws often come next on the list.

Permit Requirements And Height Limits

In Ottawa–Gatineau, fence regulations differ from one neighbourhood to another. A quick check of your local bylaw can save you headaches down the road.

“Ensuring you stay within your local bylaw limits is essential to avoid fines and rebuilds,” advises a FenceScape compliance specialist.

In most areas:

Front yard fences may not exceed 1.2 m without a special permit.

Rear and side fences can go up to 1.8 m before extra approval is needed.

Posts typically must sit at least 0.6 m back from the property line.

To keep things running smoothly:

Submit a permit application if your fence surpasses local height limits or borders a pool.

Arrange inspections before and after the posts are set to ensure full compliance.

FenceScape technicians can visit your property to evaluate soil conditions, recommend board spacing and post gauge, and provide a detailed scope of work. They’ll even bring material samples and colour swatches so you can make on-site decisions with confidence.

Ready to transform your outdoor space? Contact FenceScape to schedule your free estimate: FenceScape

Comments