A Homeowner's Guide to Pressure Treated Fence Wood

- Eric Lafleche

- Dec 29, 2025

- 11 min read

At its core, pressure treated fence wood is everyday lumber—usually pine—infused with preservatives to fight off rot, insects, and decay. This process makes it tough enough to handle the Ottawa–Gatineau climate, turning vulnerable lumber into a resilient, affordable, and long-lasting material for any outdoor project.

This guide provides the actionable insights you need to choose, install, and maintain a pressure-treated fence that lasts for decades.

What Exactly Is Pressure Treated Fence Wood

In a region with humid summers and harsh freeze-thaw cycles, untreated wood quickly succumbs to moisture, rot, or termites. Pressure-treated wood is specifically engineered to overcome these challenges.

The "pressure" in its name is key. Standard lumber is placed in a sealed chamber where a vacuum removes air from the wood's cells. Then, a chemical preservative is pumped in and forced deep into the wood’s fibres under immense pressure. This isn't a surface coating; it's a deep infusion that protects the lumber from the inside out.

The Purpose of Treatment

The primary goal of the treatment is to make the wood inhospitable to organisms that cause it to break down. This chemical shield provides several practical advantages for your fence:

Rot Resistance: The preservatives stop fungi and bacteria from growing, which is critical for posts in direct contact with damp soil.

Insect Repellence: Pests like termites and carpenter ants are repelled by the chemicals, safeguarding your fence's structural integrity.

Enhanced Longevity: This protection means a properly installed and maintained pressure-treated fence can last for 20 years or more, offering an excellent return on your investment.

Actionable Insight: By choosing pressure-treated wood, you are opting for a high-performance material that combines the affordability of common lumber with the durability needed to withstand years of outdoor abuse.

More Than Just a Green Tint

You can typically identify pressure-treated wood by its signature greenish or brownish hue, which comes from the copper-based preservatives. Don't get attached to this colour; exposure to the sun will cause it to fade to a silvery grey over time. You can preserve or change this look with a quality stain.

To learn more about the material itself, you can dive deeper into our guide on what is pressure treated lumber for outdoor projects.

This highly effective process transforms a vulnerable organic material into a durable, dependable building block. You get the natural beauty and workability of real wood without the worry of premature failure, making it the go-to choice for countless outdoor structures.

How the Pressure Treatment Process Works

Understanding how pressure treated fence wood is made helps you appreciate its durability. This high-pressure process forces preservatives deep into the wood’s fibres, fundamentally changing it from the inside out.

The process begins by loading lumber into a large, sealed steel cylinder called a retort. A powerful vacuum sucks all the air out of the wood's cellular structure, creating a void that prepares the lumber to absorb the preservative solution.

Forcing Protection Deep Inside

Once the vacuum cycle is complete, the cylinder is flooded with a liquid preservative. Immense hydraulic pressure is then applied, forcing the chemical solution into every pore and fibre. This deep penetration ensures the preservative doesn't just sit on the surface but protects the wood right to its core.

This saturation is what provides long-term defence against decay. After the pressure phase, the excess solution is drained, and the treated wood is left to cure. During this time, the chemicals bond with the wood fibres, creating a permanent shield.

Actionable Insight: The treatment process guarantees that every part of the lumber gains long-lasting resistance. When purchasing, look for an end tag that specifies the chemical used and its intended use (e.g., "Ground Contact").

The Modern Preservatives Used in Canada

The chemicals used today are a far cry from older, arsenic-based treatments (like CCA), which are banned for residential use in Canada. Modern pressure treated fence wood uses copper-based formulas, as copper is a natural and effective fungicide and insecticide.

Here’s a practical guide to the preservatives you'll find for residential fencing in Canada.

Modern Wood Preservatives At a Glance

Preservative Type | Key Components | Best For | What You Need to Know |

|---|---|---|---|

Alkaline Copper Quaternary (ACQ) | Copper oxide and a quaternary ammonium compound. | Fences, decks, landscaping timbers, and general outdoor construction. | One of the first widely adopted, arsenic-free alternatives. |

Copper Azole (CA) | Copper paired with azole co-biocides. | Similar uses to ACQ, often preferred for its slightly more natural colour. | Lower copper content than ACQ while still providing excellent protection. |

The preservatives used in lumber yards today, like ACQ and Copper Azole, are approved by Canadian health and environmental agencies. They deliver robust protection without the health risks of older chemicals, so you can confidently use them in your backyard.

While this high-tech method is standard, there are fascinating alternative woodworking and wood preservation techniques like the ancient Japanese art of Shou Sugi Ban.

Ultimately, understanding this controlled process gives you confidence that your fence is built with modern, safe preservatives locked in to ensure it lasts.

The Pros and Cons for Ottawa Homeowners

Choosing a fencing material requires weighing its benefits against its drawbacks. For Ottawa homeowners, pressure-treated fence wood offers compelling value and durability, but it's essential to understand the trade-offs. This breakdown will help you decide if it aligns with your budget, aesthetic goals, and maintenance willingness.

The Clear Advantages of Treated Wood

The widespread popularity of pressure-treated fences comes down to unbeatable value. You get a durable fence for significantly less than premium options like cedar or PVC vinyl.

Beyond price, its performance in our climate is a major advantage. The chemical treatment provides a shield against the two biggest threats to outdoor structures in the Ottawa–Gatineau region:

Exceptional Rot Resistance: The copper preservatives prevent the growth of fungus and bacteria, which is crucial for fence posts that sit in damp soil.

Powerful Insect Defence: The treatment repels termites and carpenter ants, keeping your fence's structure solid for years.

Furthermore, its widespread availability at all lumber yards and home improvement stores makes it easy to source materials for new projects or repairs.

Actionable Insight: For a durable, long-lasting fence that offers fantastic protection against rot and insects without breaking the budget, pressure-treated fence wood is the most practical and cost-effective choice.

The Potential Downsides to Consider

Pressure-treated wood isn't perfect. Be aware of these potential drawbacks to manage your expectations and ensure the best results. Most issues stem from the high moisture content immediately after treatment. As this water evaporates, the wood can move.

This can result in some boards twisting, warping, or cracking. You can minimize this by allowing the wood to dry properly before staining or sealing it. Careful installation is also key to preventing movement.

Aesthetically, the wood's initial greenish hue fades to a grey over the first year. If this isn't your desired look, a quality stain can easily change its appearance, but this requires an additional step.

Finally, while modern chemicals like ACQ and Copper Azole are arsenic-free and approved for residential use, always handle treated wood with care. Wear gloves when working with it and wash your hands thoroughly afterward. Knowing these characteristics helps you get the best possible performance from this highly practical fencing material.

Pressure Treated Wood vs Cedar and Vinyl Fences

Choosing your fence material is a balance of budget, longevity, maintenance, and aesthetics. In the Ottawa–Gatineau area, the decision often comes down to three choices: pressure-treated wood, cedar, and PVC vinyl.

Pressure treated fence wood is the workhorse—the champion of value. Cedar offers classic, natural beauty. Vinyl is the modern, low-maintenance alternative. Let's compare them directly to help you make the right choice for your property.

Fence Material Showdown for Ottawa Homeowners

This table provides a clear, side-by-side comparison to help you prioritize what matters most.

Feature | Pressure-Treated Wood | Cedar | PVC (Vinyl) |

|---|---|---|---|

Upfront Cost | Lowest | Moderate to High | Highest |

Lifespan | 20+ years (with care) | 15-25 years | 30+ years |

Maintenance | Regular staining/sealing | Staining to preserve colour | Occasional washing |

Look & Feel | Natural wood, paintable | Rich, natural reddish tones | Clean, uniform, modern |

Durability | High (chemically protected) | High (naturally resistant) | Very High (immune to rot) |

As you can see, the "best" material depends on your top priority: initial cost, long-term ease, or a specific look.

The Upfront Cost Showdown

For most homeowners, budget is a primary factor, and this is where pressure-treated wood excels. It is consistently the most budget-friendly fencing material available. The cost advantage is significant on larger properties, as pressure-treated pine can be 30–60% cheaper per linear foot than premium woods like cedar. This affordability keeps it the top seller in the wood fencing market, a sector projected to be worth USD 9.1 billion by 2025.

Cedar sits at a higher price point, while vinyl typically requires the largest initial investment, though its near-zero maintenance costs can offset this over time.

Lifespan and Long-Term Durability

How long will your fence withstand Ottawa's weather? All three materials are durable, but achieve it differently.

Pressure-Treated Wood: With proper installation and basic care, expect a lifespan of 20 years or more. The chemical treatment provides a robust shield against rot and insects.

Cedar: Its natural oils provide inherent resistance to rot and insects. A well-maintained cedar fence typically lasts 15 to 25 years.

PVC Vinyl: For pure longevity, vinyl wins. It is immune to rot and insects and can last 30 years or longer with minimal effort.

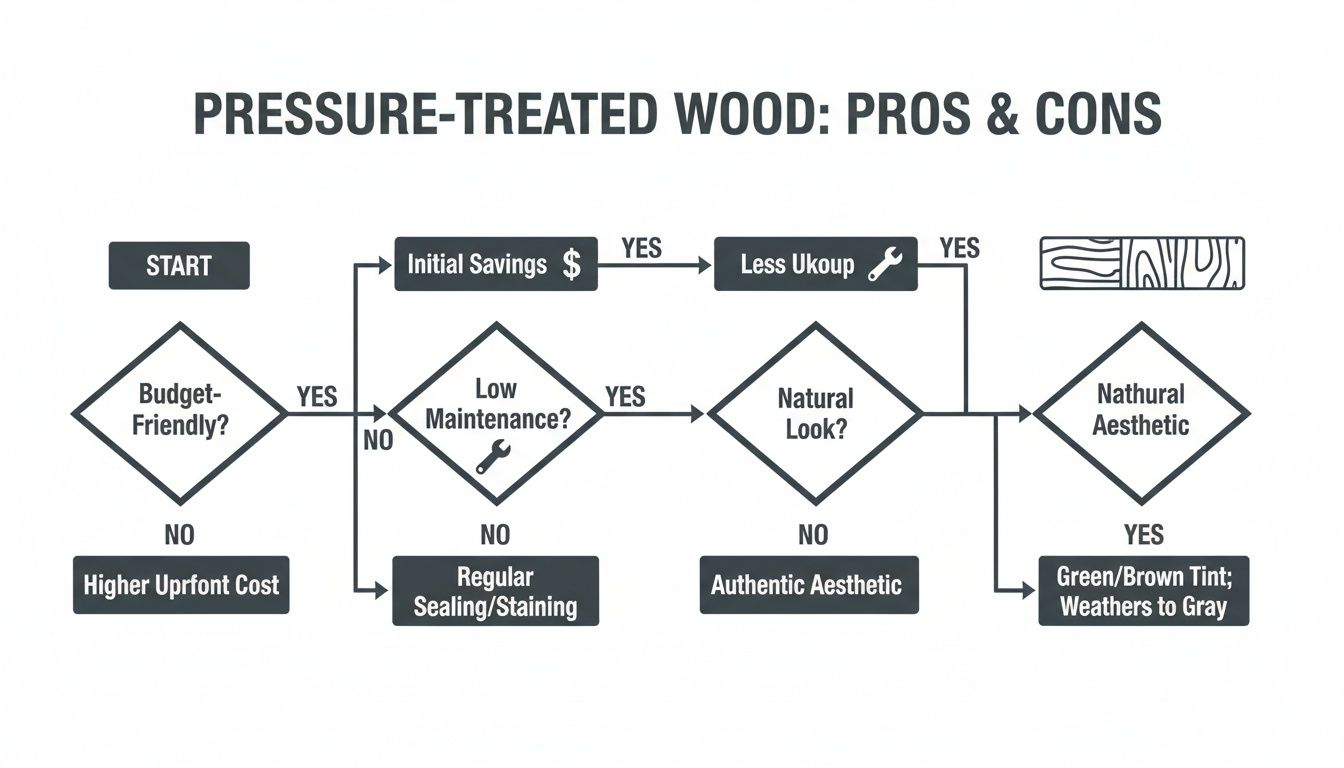

This flowchart can help you visualize the decision-making process.

It highlights how budget often drives the choice, while reminding you to consider aesthetics and long-term maintenance.

Maintenance Needs and Aesthetic Appeal

The long-term effort required to maintain your fence is a critical factor where these materials differ significantly.

Pressure-treated wood requires the most hands-on care. To prevent warping and fading, apply a quality stain or sealer every two to three years. This commitment also provides creative freedom, allowing you to change your fence's colour whenever you wish.

To better understand the practical differences, explore our detailed article on the differences between cedar and pressure-treated fences.

Cedar needs similar care if you want to preserve its rich, reddish hues. If left untreated, it will weather to an attractive silvery grey.

Vinyl fencing is the easiest to maintain. It never needs painting or staining; a simple wash with soap and water once a year is sufficient. It offers a clean, modern look but lacks the natural texture of real wood.

Decision Point: Choose pressure treated fence wood for unbeatable value and a customizable, classic wood look. Opt for cedar if your budget allows for a premium, natural aesthetic. Select vinyl for a "set it and forget it" solution with maximum longevity.

How To Install and Maintain Your Fence

A fence built with the best pressure treated fence wood will only last if it's installed correctly and properly maintained. Protecting your investment begins with a solid foundation, especially given the dramatic freeze-thaw cycles in the Ottawa–Gatineau region.

The single most critical step is setting the posts correctly. Ground heave can push improperly set posts upward, resulting in a crooked fence within a few years. To prevent this, you must dig post holes below the local frost line. In our area, this means digging at least four feet (1.2 metres) deep to anchor the footing in stable soil.

The Foundation a Professional Installation Provides

While DIY fence building can be rewarding, professional installation ensures precision. A skilled crew guarantees every post is plumb, every rail is level, and all fasteners are corrosion-resistant (e.g., hot-dipped galvanized or stainless steel). This expertise prevents common issues like sagging gates and wobbly sections. For maximum stability, setting posts in concrete is the industry standard. Learn the correct technique in our guide to get a rock-solid foundation.

Actionable Insight: The longevity of your fence is determined on installation day. Proper post depth isn't just a recommendation—it's essential for surviving our local climate.

A Simple Seasonal Maintenance Plan

Once your fence is installed, follow this simple plan to keep it looking great and maximize its lifespan.

1. Let It Dry Before Finishing (The Waiting Game)

Do not stain or paint new pressure-treated wood immediately. It is still saturated with moisture from the treatment process. Sealing it too soon traps this moisture, causing the finish to peel and blister. Wait several weeks or even a few months for it to dry completely.Action Tip: Sprinkle water on the wood. If it beads up, it’s still too wet. If it soaks in, it’s ready for finishing.

2. Perform an Annual Cleaning

Each spring, clean your fence to remove dirt, mildew, and algae that trap moisture. Use a bucket of water with a mild detergent and a soft-bristle brush. For tougher grime, use a dedicated wood cleaner. Avoid high-pressure power washers, as they can damage the wood fibres.

3. Apply a Protective Finish Every 2-3 Years

A quality stain or water-repellent sealant is crucial. It protects the wood from UV rays that cause it to turn grey and brittle, and it prevents moisture absorption that leads to warping and cracking. Proper surface preparation is key to a lasting finish. You can find excellent guides on preparing wood for finishing to walk you through the steps.

This simple routine—wait, clean, and seal—is all you need to protect your investment and ensure your pressure treated fence wood lasts.

Using Treated Wood for Pool Fences

For pool owners, safety is non-negotiable. Pressure-treated fence wood provides a strong, reliable, and compliant enclosure that meets local by-laws in Ottawa and Gatineau, giving you total peace of mind.

The purpose of a pool fence is to create a barrier that prevents young children from accessing the pool area unattended. Using pressure-treated wood makes it affordable and straightforward to build a fence that meets these strict safety requirements.

Meeting Local Pool Safety Standards

A pool fence is a critical safety feature. The structural strength of pressure-treated wood, especially for posts set deep in the ground, ensures your fence remains rigid and secure.

A properly constructed treated wood fence can easily meet key local by-laws:

Minimum Height: The fence must be at least 1.5 metres (5 feet) high to prevent climbing.

Climb-Resistant Design: Use vertical boards with minimal spacing and no horizontal rails on the outside that could serve as a ladder.

Self-Latching Gates: All pool gates must swing outward (away from the pool) and be equipped with self-closing and self-latching hardware placed high out of a child's reach.

Actionable Insight: The inherent strength of pressure-treated wood is ideal for these safety standards. Setting posts in concrete creates a solid, permanent barrier. For any fence post near a pool, pressure-treated lumber is the only practical choice due to its moisture resistance.

Contractors in regions with similar regulations rely on pressure-treated posts for 60–80% of wood pool fences because of their proven durability. You can find more insights on why pressure-treated lumber is a top choice for fences on palisadefenceco.com.

By choosing pressure-treated wood, you are building a compliant safety system that protects your family without compromising your budget.

Your Top Questions About Treated Fences, Answered

Here are clear, practical answers to the most common questions homeowners ask about pressure-treated fence wood.

Is Pressure-Treated Wood Safe for My Family and Pets?

Yes. Modern pressure-treated wood is safe for residential use. The arsenic-based chemicals of the past have been replaced with copper-based preservatives (like ACQ and CA) approved by Canadian health and environmental agencies. These chemicals are bonded within the wood's fibres and do not easily leach into the soil. For a finished fence in your yard, it is perfectly safe for children and pets.

Should I Stain or Paint My New Fence Right Away?

No. This is a critical mistake. New pressure-treated lumber is still wet from the treatment. Sealing it prematurely traps moisture, causing the finish to peel.Actionable Tip: Wait for the wood to dry completely, which can take several weeks to a few months. Test it by sprinkling water on a board. If the water beads up, wait longer. If it soaks in, the wood is ready to absorb the stain.

How Long Will a Pressure-Treated Fence Actually Last?

In the Ottawa–Gatineau climate, a properly installed pressure-treated fence will last 20 years or more. The two most important factors determining its lifespan are the quality of the installation (especially setting posts below the frost line) and performing basic maintenance, like sealing it every few years.

Bottom Line: A well-built treated fence is a long-term investment. The treatment process provides a powerful defense against rot and insects, giving it the strength to stand for decades.

Do I Really Need to Clean My Fence?

Yes. An annual cleaning is a simple and effective part of maintenance. Over the year, your fence collects dirt, pollen, and mildew, which can trap moisture against the wood and accelerate decay. A gentle wash each spring with a mild detergent and a soft brush removes this grime, allows the wood to dry properly, and keeps it looking its best. This small task prevents larger problems later on.

Ready to build a fence that stands the test of time? The experts at FenceScape are here to help. We specialize in professional fence installation using high-quality materials designed for the Ottawa–Gatineau climate. Contact us today for a free estimate and let's bring your vision to life.

Comments