A Guide to Fencing for Construction Sites

- Eric Lafleche

- Nov 22, 2025

- 15 min read

When you picture a construction site, what's the first thing you see? Probably the fence. It's the essential temporary barrier that goes up before anything else, wrapping the entire job site in a protective layer. But it’s so much more than just a boundary marker—it’s your project's first line of defence against theft, liability, and costly delays.

Choosing the right fencing isn't just about ticking a box; it's a critical decision for managing risk from the get-go.

Why Fencing Is Your First Line of Defence

Think of construction fencing as the temporary shield for your entire project. It's that non-negotiable first step that protects your people, your assets, and the public. While it might seem like a straightforward requirement, its role is foundational to a successful build, impacting everything from site security to your bottom line.

A well-fenced perimeter does more than just keep people out. It creates a controlled, professional environment where your team can work safely and efficiently. Without that boundary, you're leaving your project wide open to all sorts of problems that can have serious financial and legal blowback.

The Three Pillars of Site Protection

At its core, effective construction fencing rests on three pillars: security, safety, and compliance. Each one tackles a different kind of risk, and together, they form a secure bubble around your operations.

Security: Let's face it, construction sites are a magnet for thieves. With all that valuable equipment and material just sitting there, it's an easy target. In the U.S. alone, an estimated $1 billion in equipment is stolen from sites every year. A solid fence is your most basic physical deterrent, making it much harder for thieves to slip in and out unnoticed.

Safety and Liability: An open construction site is a minefield of hazards for the public, especially curious kids. A proper fence is what keeps them out, dramatically cutting down your risk of accidents and the liability claims that can stop a project in its tracks.

Compliance: In Ottawa and across Ontario, regulations like the Occupational Health and Safety Act (OHSA) demand that construction sites are properly secured. The right fencing ensures you’re meeting those legal requirements, helping you steer clear of hefty fines, stop-work orders, and damage to your reputation.

We often see fencing as a passive barrier, but its real value is proactive. It’s the first strategic move you make to actively manage risk, control who comes and goes, and protect your investment from day one.

Understanding these functions helps you select a fence that isn't just a cost but an indispensable tool for keeping your project on track, on budget, and out of trouble. This is the foundation for making smart choices about the kind of fencing that will truly protect you.

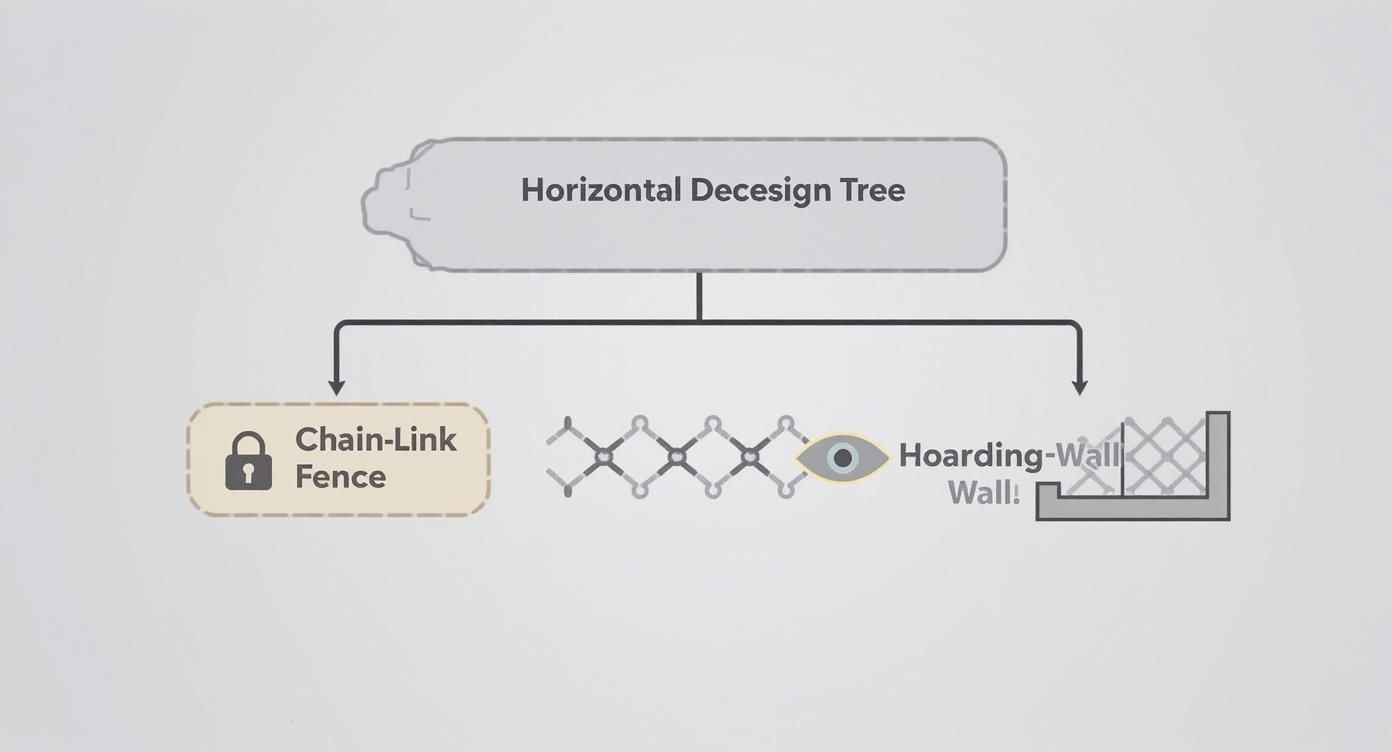

Choosing the Right Type of Construction Fencing

Picking the right fence for a construction site isn’t a one-size-fits-all deal. It's a strategic choice based on your site's specific needs. Every type of construction fencing brings something different to the table, offering its own mix of security, privacy, and cost-effectiveness for different kinds of projects.

To make the right call, you have to assess what your site truly needs. Is it in a busy downtown area or a quiet suburb? How long will the project run? What are the security risks? Answering these questions helps you match the fence to the job, turning a simple boundary into a valuable asset that protects your project from day one to completion.

Temporary Chain-Link Fencing: The Versatile Workhorse

Walk past most construction sites, and you'll likely see temporary chain-link fencing. There’s a good reason for that—it’s the go-to choice for establishing a secure perimeter quickly and cost-effectively. Its open-weave design lets you see what’s happening on-site, which is great for general monitoring.

Actionable Insight: Choose chain-link when your main goals are access control and basic theft deterrence, and you aren't concerned about hiding the work from public view. The modular panels are easy to set up, reconfigure as the site evolves, and remove at project completion. If you need a reliable, no-fuss security solution, exploring different chain-link fencing options is the practical first step.

The main drawback is its visibility. Chain-link does nothing to contain dust and debris and puts the entire messy reality of a construction site on full display, which can be a problem in high-traffic urban settings.

Plywood Hoarding: The Privacy and Dust Shield

When your project is smack in the middle of a bustling downtown core or right up against a residential neighbourhood, your priorities shift. This is where plywood hoarding really shines. Hoarding creates a solid wall, completely blocking the view into the site. It gives you maximum privacy while shielding the public from construction noise and mess.

Actionable Insight: Opt for plywood hoarding when public-facing presentation and containment are critical. The solid barrier is your best tool for controlling dust and debris, helping you meet municipal by-laws and maintain good community relations. Hoarding also doubles as a massive billboard—it’s the perfect canvas for your company logo, project renderings, or other advertising.

Hoarding fencing is like a visual and physical curtain around your project. It’s less about just keeping people out and more about managing how the public experiences the site—controlling what they see, hear, and are exposed to.

Of course, all that privacy and protection comes at a price. Hoarding is generally more expensive and takes longer to install than chain-link. Its solid surface also catches the wind like a sail, so it needs serious bracing to stay upright and safe.

Welded Wire Mesh: The Robust Security Upgrade

For sites where security is non-negotiable, welded wire mesh is a major step up from standard chain-link. These panels are made from thick steel wires welded together at every crossing point. The result is a rigid, anti-climb grid that’s incredibly tough to cut or bend.

Actionable Insight: Select welded wire mesh to protect high-value assets like heavy equipment or copper wiring—both prime targets for thieves. The small gaps make it almost impossible for someone to get a foothold to climb over or pass tools through.

This level of security costs more, but for a long-term project or a site in a high-risk area, that investment can easily pay for itself by preventing a single major theft. The demand for tougher security is a trend seen across the continent. The U.S. fencing market, for example, was valued at about $9.33 billion and is expected to hit nearly $14.9 billion by 2033, largely because urban construction demands more durable products.

Choosing the right fence involves weighing these pros and cons against your specific site needs and budget. This table breaks it down to make the decision a bit easier.

Comparing Common Construction Fencing Types

A side-by-side comparison of construction fencing options to help you choose the best fit for your project's needs.

Fence Type | Best For | Pros | Cons |

|---|---|---|---|

Temporary Chain-Link | General perimeter security, short-to-medium term projects. | Cost-effective, quick installation, highly flexible, good visibility. | Low privacy, minimal dust control, can be cut with tools. |

Plywood Hoarding | High-traffic urban areas, long-term projects, sites needing privacy. | Excellent privacy, great dust/debris control, branding opportunities. | Higher cost, longer installation time, requires wind bracing. |

Welded Wire Mesh | High-security needs, protecting valuable assets, anti-climb deterrence. | Extremely durable, difficult to cut or climb, superior security. | Most expensive option, can be heavier to install. |

Ultimately, the best fence is the one that gives you peace of mind, knowing your site, your assets, and the public are all properly protected.

Navigating Safety Regulations and Local By-Laws

Putting up a fence around your construction site isn't just about drawing a line in the sand. It's a non-negotiable legal requirement, governed by both provincial and municipal rules. Get it wrong, and you're looking at hefty fines, stop-work orders, and liability issues that can derail your entire project.

Actionable Insight: Treat these regulations as your project's safety blueprint, not as red tape. They provide clear standards to keep your crew, the public, and your assets safe. Understanding this framework transforms your fence from a simple expense into an effective risk management tool, ensuring your site is compliant from day one.

Provincial Oversight: The Occupational Health and Safety Act

In Ontario, the Occupational Health and Safety Act (OHSA) sets the standard. The Act demands that employers take every reasonable precaution to protect everyone—workers and the public alike. For a construction site, that starts with a secure, controlled perimeter.

A core principle of the OHSA is to block unauthorized people from getting into hazardous areas. This makes your construction fence the first and most visible line of defence. A gap in the fence isn't just a security lapse; it's a potential violation of provincial law.

Thinking through your site's main needs—like basic security versus total privacy—is the first step to getting your fencing right.

As you can see, if you just need to keep people out, standard chain-link often does the trick. But if you're dealing with a busy public area where dust, debris, and privacy are major concerns, hoarding becomes the only way to meet your compliance obligations.

Diving into Municipal By-Laws

If the OHSA tells you what to do, it’s the local municipal by-laws in places like Ottawa and Gatineau that tell you how to do it. These local rules provide the specific details that directly affect your fence installation, and they can change significantly depending on your project’s location and scope.

Actionable Insight: Before ordering any fencing, check the specific municipal codes for your project's location. This step builds your fencing strategy on a solid legal foundation, protecting your schedule and budget from avoidable headaches.

Here are a few key specs typically covered in municipal by-laws:

Minimum Fence Height: Most cities mandate a minimum height, usually around 1.8 metres (6 feet), to be a credible deterrent against climbing.

Structural Stability: This is a big one. Solid hoarding panels, in particular, must be braced to handle local wind loads. Proper footings and support aren't just a good idea; they're the law.

Secure Gate Access: Your gates need to be lockable and close without leaving gaps someone could slip through. Gates are a common weak point and something inspectors always check.

Required Signage: By-laws will often specify that you need to post clear signs—like "Danger," "No Trespassing," or contact info for the site superintendent.

Failing to comply is more than a simple oversight; it's a surefire way to disrupt your project. A single by-law infraction can bring an inspector to your site and trigger a stop-work order, grinding everything to a halt until it's fixed. The cost of that downtime will almost always be more than the cost of doing it right the first time.

A job site in a dense downtown Ottawa neighbourhood will have far stricter hoarding and pedestrian safety rules than a new build in a quiet suburb. Proactively checking the local codes is a simple action that prevents major project disruptions.

Budgeting for Fencing: Should You Rent or Buy?

One of the first big questions you'll face on any project is whether to rent or buy your temporary fencing. It's a classic cash flow puzzle, and the right answer really boils down to how often you'll be breaking ground.

For a one-off job or for builders who only have a few projects on the go each year, renting is almost always the smarter financial move. This converts a large capital expenditure into a manageable operating expense and eliminates the costs of storage, transport, and maintenance.

On the other hand, if you're a large-scale developer or a general contractor with a constant pipeline of work, buying your own fencing can save you a bundle in the long run. The initial investment hurts, but after a few projects, that fence becomes an asset that’s making you money instead of costing you money. This only works if you have the yard space and manpower to manage your own inventory, of course.

What Really Drives Your Fencing Costs?

Whether you rent or buy, a few key factors will shape the final bill for your fencing for construction. Getting a handle on these variables is the key to building a budget that doesn't come back to bite you later.

Here’s what you need to nail down:

Linear Footage: This is the big one. How long is your perimeter? The total length directly determines how many panels, posts, and bases you’ll need, making it the primary driver of your cost.

Fence Type: As we've seen, not all fences are created equal. A basic temporary chain-link fence is your most budget-friendly option. If you need something beefier like high-security welded mesh or solid plywood hoarding for privacy, expect the price to climb accordingly.

How Long You Need It: If you're renting, the project timeline is critical. Most suppliers price by the week or month, and you can often negotiate a better daily rate for a longer-term rental.

The Extras: Don't forget the add-ons. Things like privacy screening, branded banners for marketing, and dedicated gates for people or vehicles will all add to the bottom line. These are usually priced out per item or panel.

The rent vs. buy decision is all about strategy. Renting gives you flexibility and keeps upfront costs low, making it perfect for most situations. Buying is an investment that only pays off if you can guarantee consistent, long-term use across many job sites.

Sample Budget Scenarios for Rental Fencing

To make this more concrete, let's look at what some real-world rental scenarios might cost. These are just ballpark figures to help you plan, but they show how quickly costs can change based on the size and needs of your project. Always get a formal quote before finalizing your budget.

The demand for construction fencing is huge, making it a surprisingly large industry. To put it in perspective, the fence construction sector in California alone was valued at around $1.7 billion. You can dig into more data on the industry's economic impact to understand the market forces that influence pricing.

Here’s a rough idea of what to budget for different jobs.

Sample Construction Fencing Budget Scenarios

Estimated weekly rental costs for different types of construction projects to aid in budget planning.

Project Type | Perimeter Length (Linear Feet) | Fence Type | Estimated Weekly Rental Cost |

|---|---|---|---|

Small Residential Reno | 150 ft | Temporary Chain-Link | $100 - $175 |

Single-Family Home Build | 400 ft | Chain-Link with Privacy Screen | $350 - $500 |

Commercial Building Site | 800 ft | Plywood Hoarding | $900 - $1,300 |

Large Infrastructure Project | 2,000 ft | Welded Wire Mesh | $2,200 - $3,000+ |

Actionable Insight: Measure your perimeter accurately and clearly define your security and privacy needs before requesting quotes. This upfront work allows you to build a realistic budget and avoid unexpected costs later in the project.

Planning Your Fence Installation and Site Prep

A secure fence is only as good as the groundwork you lay for it. Rushing to get a fence up without proper site prep is a surefire way to hit delays, create safety hazards, and watch your budget swell with unexpected costs. A little bit of planning upfront ensures your perimeter is solid from day one, heading off security gaps and logistical headaches before they start.

This isn't just about clearing a path. It’s about creating a stable, safe, and truly functional boundary. Smart planning means thinking through where your access points will be, timing the fence delivery with your project schedule, and—critically—avoiding the costly mistake of hitting an underground utility line.

Your Pre-Installation Site Prep Checklist

Before the first fence panel even hits the site, there are a few things you absolutely have to take care of. Think of it as setting the stage. A clean, prepared site means your fencing contractor can work efficiently and safely, getting your perimeter buttoned up much faster.

Here’s a practical checklist to get your site ready:

Mark and Clear the Fence Line: Walk the perimeter and mark it out clearly with stakes or spray paint. Then, clear that line of everything—debris, overgrown bushes, rocks, stray equipment. You need a completely open path for the crew to work.

Level Uneven Ground: Temporary fencing needs a reasonably flat, stable surface to rest on. Take the time to fill in any major ruts and knock down any big bumps along the marked line. This keeps the fence bases secure and the panels standing straight instead of leaning.

Locate All Underground Utilities: This is the one step you cannot skip. Before anyone puts a shovel or stake in the ground, you must call your local utility locating service (like Ontario One Call). They’ll come out and mark all the buried gas, water, electrical, and communication lines. Hitting a utility line is a massive headache—it's dangerous and incredibly expensive.

Getting these steps done right creates a safe, efficient workspace for the install crew, which is the foundation for a secure site.

A well-prepared site sets the tone for the entire project. When you clear the path and eliminate potential hazards beforehand, you’re not just making the fence installation easier—you’re reinforcing a culture of safety and foresight from the very beginning.

Coordinating Logistics and Access Points

Once the ground is prepped, it's time to think about logistics. Your fence isn't just a static barrier; it's going to be a key part of your site's daily rhythm. Poorly placed gates can create massive bottlenecks for workers, deliveries, and heavy machinery.

Give these logistical points some serious thought:

Strategic Gate Placement: Where do you need access for heavy equipment? Where will materials be delivered? And where will your crew be coming and going? If the site is big enough, setting up separate gates for vehicles and pedestrians is a great way to improve safety and keep things moving smoothly.

Delivery and Staging Area: Pick a spot that’s easy for a large truck to get to. This is where the fencing materials will be dropped off and staged. The last thing you want is a delivery truck blocking the main entrance or getting stuck in the mud.

Timeline Coordination: The fence should be one of the very first things to go up. Your goal is to have the site fully secured before any valuable equipment or materials show up. This simple bit of scheduling is one of the best theft deterrents there is.

Keep in mind that the timing can also be affected by seasonal demand. Search interest for 'temporary construction fencing' tends to shoot up between April and August, right in the thick of prime construction season. You can check out more about these seasonal fencing trends on yourgreenbuilders.com.

Actionable Insight: Map out your gate locations and delivery access on your site plan early. Coordinate with your fencing provider to ensure the fence is installed before the first major equipment delivery to maximize security from day one.

How to Choose the Right Fencing Partner

When you're looking for a temporary fencing provider, it's tempting to just go with the lowest bid. But that's often a mistake. You're not just buying fence panels; you're hiring a partner whose work directly affects your site's security, safety, and even your project's timeline.

A great partner doesn't just drop off a fence. They install it properly, understand the flow of a construction site, and are ready to respond when things inevitably change. They become a key part of your team, helping you anticipate problems before they happen and making sure your perimeter is solid from day one to the final cleanup.

Essential Questions for Vetting Contractors

Before you sign on the dotted line, you need to ask some hard questions. This isn't just a formality—it’s how you separate the true professionals from the pack. Think of it as a job interview for a crucial member of your site crew.

Here’s a quick checklist to run through with any potential contractor:

Experience and Specialization: Have they handled projects of your size and type before? A company that specializes in fencing for construction knows the unique demands of a job site in a way a residential installer simply won’t.

Insurance and Compliance: This is non-negotiable. Ask for proof of current liability insurance and WSIB/CSST coverage. Without it, you’re exposing your entire project to massive risk.

Knowledge of Local By-Laws: Can they speak confidently about Ottawa–Gatineau’s specific fencing regulations? A good contractor knows the local codes for height, bracing, and signage requirements inside and out.

A transparent quote is a sign of a professional partner. Vague line items or hidden fees are red flags. Your quote should clearly detail costs for materials, installation, any add-ons like privacy screens, and removal at the project's end.

Evaluating Service and Reliability

The real test of a fencing partner comes after the initial installation. Construction sites are living, breathing things. You need a contractor who can keep up.

What happens when a delivery truck backs into a panel or a windstorm takes a section down? A security breach is an emergency. Look for a company with a clear service agreement that guarantees a response time—a 24-hour turnaround should be the absolute standard.

A truly reliable contractor acts as an extension of your own site management team. By asking the right questions upfront, you can find a partner who takes your security as seriously as you do. To see what a dedicated local partner looks like, you can discover Fencescape’s fencing expertise in Ottawa.

Frequently Asked Questions About Construction Fencing

Even with the best-laid plans, questions always pop up once you're on the job site. Getting straight answers is the key to keeping your project on track and making sure your perimeter is actually doing its job. Here, we'll tackle the most common questions we hear from project managers about construction fencing.

Think of this as a field guide to handling the practical challenges that come up, from navigating permits to bracing for a nasty storm.

Do I Need a Permit for Temporary Fencing?

This is the big one, and the short answer is almost always yes. It might seem odd for something "temporary," but most municipalities, including Ottawa and Gatineau, require a permit if your fence encroaches on public property like a sidewalk or roadway—which hoarding almost always does.

Actionable Insight: Always assume a permit is needed, especially for urban projects. Contact your local municipal office during the planning phase to confirm requirements. This proactive step prevents fines and stop-work orders later.

How Do You Secure Fences Against High Winds?

Wind is the natural enemy of temporary fencing, especially solid plywood hoarding or any fence with a privacy screen. Those large, flat surfaces essentially turn into giant sails in a storm, and a fence collapse is a liability nightmare you don't want.

To keep a fence standing strong, we rely on a few proven techniques:

Triangular Bracing: We install support posts that run at an angle from the fence panels down to the ground. This creates a super-strong triangular shape that fights against pushing forces.

Concrete Blocks: You’ll often see heavy concrete blocks or k-rails at the base of a fence. These act as heavy-duty anchors, giving the fence the weight it needs to resist being lifted or toppled.

Wind Vents: For chain-link fences with privacy screening, a simple trick is to cut small, crescent-shaped "vents" into the material. This lets some of the wind pass right through, easing the pressure on the fence panels themselves.

A professional contractor will never just guess. They'll assess your site's specific wind exposure and design a bracing system that's built for the conditions. Never, ever underestimate what a strong gust of wind can do to a long line of fencing.

Can We Add Branding or Advertising to the Fence?

Absolutely! In fact, you should. Plywood hoarding, in particular, is a massive, blank canvas waiting to be used. It's essentially a free billboard right on your project site—perfect for plastering your company logo, showing off project renderings, or listing contact details.

Actionable Insight: To turn your fence into a marketing tool, consult with your fencing provider about custom-branded banners or vinyl wraps. Before finalizing designs, double-check local sign by-laws for any restrictions on size or content. This is a simple way to transform a safety requirement into a valuable marketing asset.

Ready to secure your next project with a reliable, professional fencing partner? FenceScape offers turnkey solutions for construction sites across the Ottawa–Gatineau region, ensuring your perimeter is safe, compliant, and installed right the first time. Learn more and get your free estimate at https://www.fencescape.ca.

Comments